Could your electrical infrastructure be silently deteriorating right now? The latest intelligent switchgear technology is revealing critical issues traditional inspections miss entirely.

The Hidden Dangers in Your Electrical Systems

Medium-voltage switchgear failures rarely come without warning. The problem? These warnings often go undetected until catastrophic failure occurs. In today's increasingly electrified world, downtime isn't just inconvenient—it's financially devastating and potentially dangerous.

Recent industry studies show that nearly 70% of electrical failures could be prevented with proper monitoring technology. This is where intelligent switchgear innovations are revolutionizing electrical safety and reliability.

What Makes Switchgear "Intelligent"?

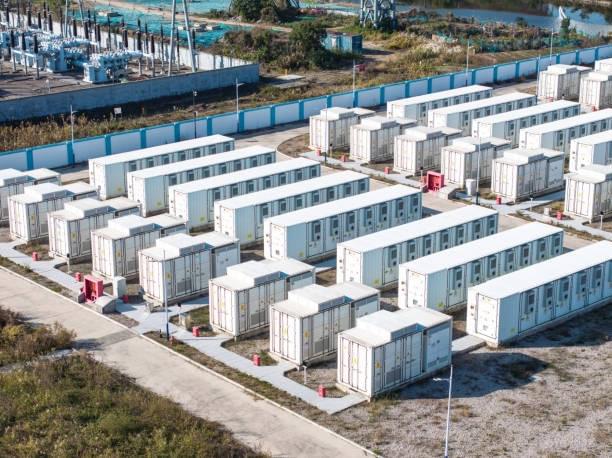

Modern intelligent switchgear systems represent a quantum leap beyond traditional equipment. At Nengfu Electrical, we've pioneered systems that don't just operate—they observe, analyze, predict, and communicate.

Intelligent switchgear focuses on two critical aspects:

- Component-level intelligence: Smart sensors and monitoring systems embedded within individual components

- System-level integration: Comprehensive platforms that analyze data across the entire electrical infrastructure

The core functionality revolves around detecting changes before they become problems and predicting future issues based on quantitative and qualitative electrical parameters. These systems use continuous online monitoring data as the foundation for maintenance decisions.

Critical Parameters Under Constant Surveillance

Temperature Monitoring: Preventing Thermal Failure

Temperature rise is one of the most telling indicators of developing problems. Excessive heat accelerates insulation aging and can lead to catastrophic failures. Our monitoring systems track temperature patterns across multiple points, detecting anomalies that could indicate:

- Installation issues: Loose bus bar connections, inadequate bolt torque, or poor cable terminations

- Operational problems: Misaligned circuit breaker contacts or improperly positioned withdrawable parts

- Material quality concerns: Substandard copper quality or poor eddy current design

- Loading issues: Operation beyond designed current ratings

- Aging concerns: Oxidized contact surfaces or ventilation blockages

Traditional manual infrared thermography simply cannot provide the continuous monitoring needed for early detection. Our 24/7 intelligent temperature monitoring systems correlate real-time load current, ambient conditions, and historical data to accurately assess risk levels and even predict failure probabilities based on anticipated load patterns.

Visual Monitoring: Seeing What Was Previously Hidden

High-definition compensated cameras now allow real-time monitoring of areas previously impossible to observe without taking equipment offline. These systems provide:

- Continuous inspection of bus bar and cable connections

- Verification of circuit breaker position and contact engagement

- Confirmation of earthing switch status

- Early detection of foreign objects or anomalies within switchgear compartments

Advanced Integration Capabilities

What truly separates today's intelligent systems from previous generations is their integration capabilities:

Integrated Visual-Thermal Analysis

By combining visual monitoring with thermal tracking, our systems can precisely determine the root causes of anomalies. For example, when temperature rises on a specific contact, the visual system can confirm whether this is due to misalignment, loose connections, or contact degradation—enabling targeted maintenance rather than costly guesswork.

Arc Flash Protection Integration

Integrated optical sensors detect arc flash events instantly, while current monitoring pinpoints the fault location. This triggers circuit breaker trips or activates high-speed earthing devices that convert air short circuits into solid short circuits—dramatically reducing damage from arc flash incidents.

Environmental Condition Monitoring

Advanced systems now incorporate micro-climate sensors that detect environmental changes within switchgear enclosures, automatically activating dehumidification systems before condensation can form on critical components.

The Nengfu Electrical Advantage

At Nengfu Electrical, we're leading the digital transformation of power systems with intelligent switchgear solutions that provide unprecedented reliability and safety. Our comprehensive approach includes:

- Design and engineering of intelligent electrical distribution systems

- Production of smart switchgear with integrated monitoring capabilities

- EPC services that incorporate the latest intelligent electrical technologies

- Retrofit solutions to bring intelligence to existing infrastructure

Our products have earned industry recognition for their exceptional performance and reliability in critical applications across diverse sectors.

The Future of Electrical Reliability

The evolution toward fully intelligent electrical systems is accelerating. The integration of AI-driven analytics with intelligent switchgear will soon enable truly predictive maintenance—identifying potential failures weeks or months before they would otherwise occur.

For facility managers and electrical engineers, this means:

- Dramatic reductions in unplanned downtime

- Extended equipment lifespan

- Lower maintenance costs

- Enhanced safety for personnel and equipment

- Improved energy efficiency through optimized operations

Take the Next Step

Don't wait for an electrical failure to consider upgrading your switchgear intelligence. Contact Nengfu Electrical today to learn how our smart medium-voltage solutions can transform your electrical reliability while reducing total cost of ownership.

Our expert team can conduct a comprehensive assessment of your current infrastructure and develop a customized intelligent switchgear strategy that addresses your specific operational challenges.

Nengfu Electrical: Powering the future with intelligent electrical solutions.