Introduction

As global ports move toward carbon neutrality and sustainable operations, upgrading existing port equipment to cleaner technologies has become essential.

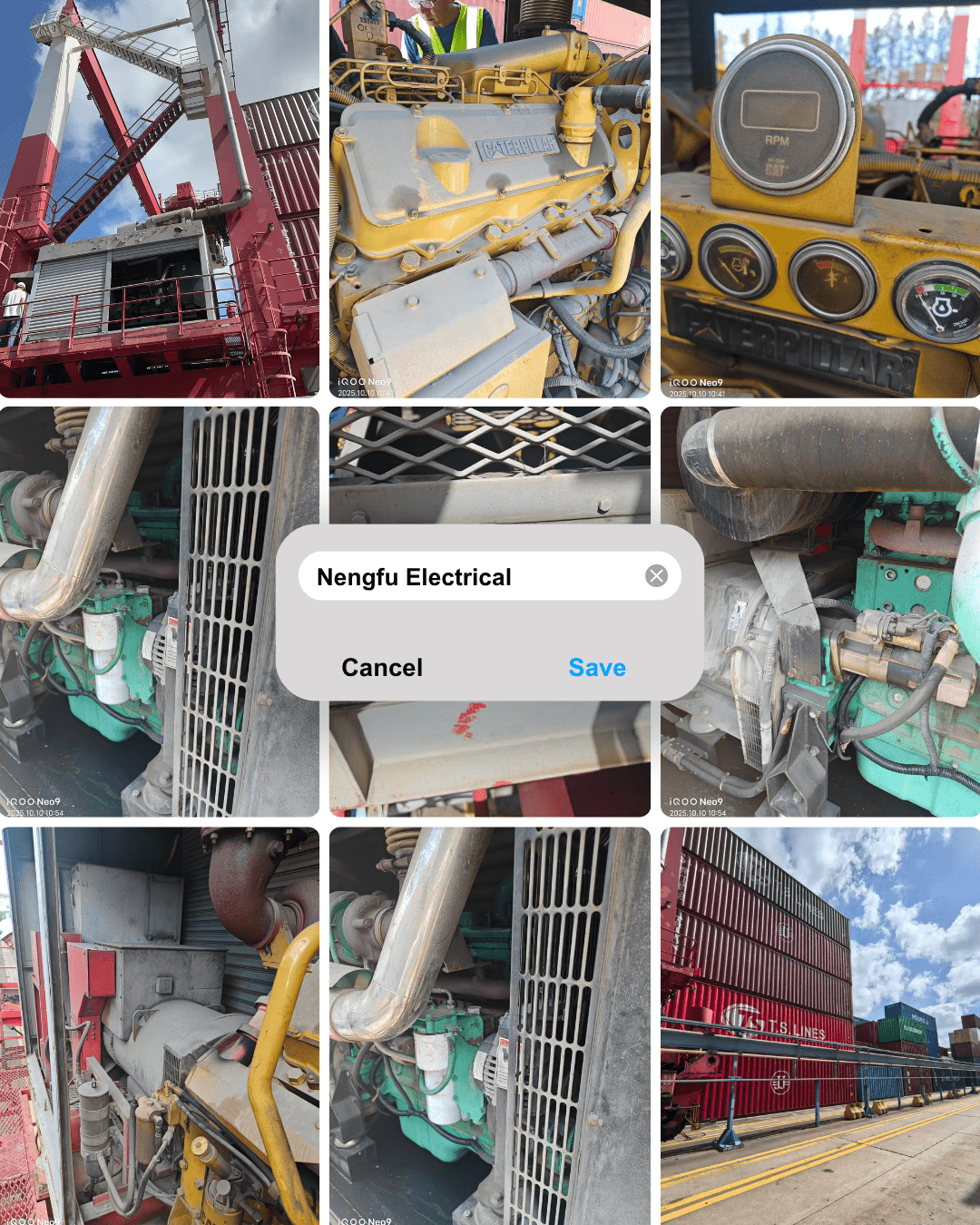

For many terminals, RTG cranes (Rubber Tyred Gantry Cranes) are still powered by traditional diesel generator sets that no longer meet current emission standards.

Nengfu offers a comprehensive RTG generator retrofit solution to comply with China Stage IV emission standards, helping ports reduce fuel consumption, cut emissions, and embrace the future of green and intelligent logistics.

Why Retrofit Your RTG Generator to Stage IV Standards?

Traditional diesel-powered RTG cranes consume large amounts of fuel and emit significant levels of nitrogen oxides (NOx) and particulate matter (PM). These pollutants not only increase operational costs but also pose environmental and compliance challenges.

Upgrading to a Stage IV-compliant diesel generator ensures:

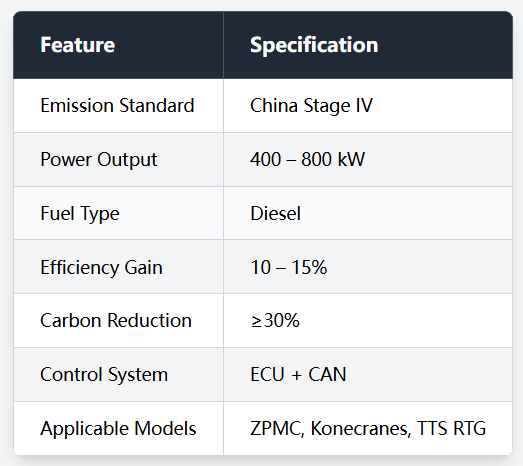

✅ Reduced Emissions-Up to 30% less CO₂and significantly lower NOx and PM levels.

✅ Improved Fuel Efficiency-10-15% fuel savings thanks to optimized combustion and smart controls.

✅Lower Noise Levels-A quieter operating environment for port workers and nearby communities.

✅ Future Compliance-Meets China's latest environmental and port operation standards.

Nengfu's Stage IV Retrofit Solution

At Nengfu, we go beyond a simple engine swap. Our retrofit service is a complete modernization package that integrates mechanical, electrical, and control upgrades.

1. Engine Upgrade

We replace the existing generator engine with a high-pressure common-rail diesel engine that fully meets China Stage IV emission standards. These engines deliver higher efficiency, lower noise, and longer service life.

2. Smart Control System

Our retrofit includes an upgraded ECU (Electronic Control Unit) and CAN communication network, allowing real-time monitoring of engine performance, fuel consumption, and emissions. Operators can access key data through an intuitive HMI for smarter energy management.

3. Modular Design

The retrofit retains the original structural layout of the RTG crane, minimizing downtime and installation complexity. Each module is designed for compatibility with major RTG brands such as ZPMC, Konecranes, and TTS.

4. Environmental and Economic Benefits

With optimized fuel mapping and advanced exhaust after-treatment, the new generator system reduces operating costs and supports corporate ESG goals.

Technical Highlights

Supporting the Green Port Transformation

Nengfu's retrofit solution supports the port industry's transition to low-carbon and intelligent operations.

Our expertise in clean diesel technology and control integration ensures that each retrofit delivers measurable environmental and economic value.

Whether your goal is regulatory compliance, fuel cost reduction, or sustainability reporting, our team provides a tailored approach to help your port stay competitive in the era of green logistics.

Conclusion

Upgrading RTG generator sets to China Stage IV standards is more than an equipment upgrade-it's a commitment to cleaner, smarter, and more sustainable port operations.

Nengfu is proud to lead this transition, offering reliable retrofit services that combine engineering excellence, environmental responsibility, and operational efficiency.