The Silent Energy Killer Lurking in Your Factory

Imagine losing $50,000 annually without even realizing it. Not through theft, not through waste, but through something happening right under your nose in your electrical system. What if I told you that a simple technology could slash your energy costs, extend equipment life, and transform your industrial efficiency?

Welcome to the world of reactive power compensation - the game-changing strategy that's revolutionizing how industries manage electrical systems in 2024.

What Exactly is Reactive Power Compensation?

Reactive power compensation is more than just a technical term - it's your financial lifeline in electrical systems. Here's why it matters:

The Real-World Impact

- Cost Reduction: Eliminate unnecessary power factor penalties

- Energy Efficiency: Reduce line current and transmission losses

- Equipment Protection: Minimize stress on electrical infrastructure

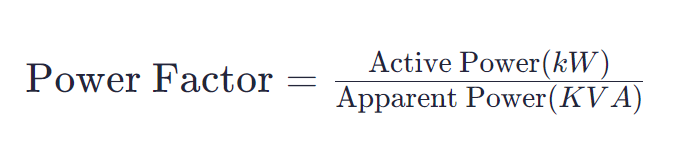

Key Metrics That Matter

The Technical Deep Dive: How Reactive Current Works

Reactive current in motors consists of two critical components:

Magnetizing Current

- Establishes magnetic flux in motor core

- Remains relatively constant across load variations

Leakage Reactance Current

- Varies with motor load

- Relatively small magnitude

Compensation Strategy: The 95% Sweet Spot

Most advanced capacitor systems can:

- Correct power factor to 95% at full load

- Maintain 95-98% power factor across load range

Critical Installation Guidelines (2024 Best Practices)

NEC Section 460 Compliance

According to the latest National Electrical Code guidelines:

- Switch gear sizing: 135% of capacitor rated current

- Ideal placement: Load side of motor contactor

- Automatic switching to prevent over-compensation

Capacitor Sizing: The Precision Approach

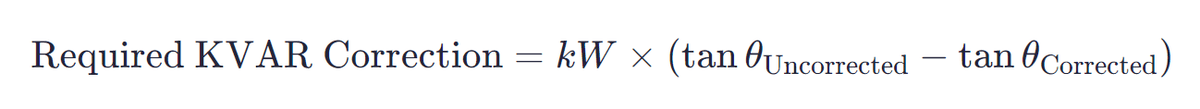

Calculation Method

Risk Mitigation

Oversizing capacitors can lead to:

- Voltage overstress

- Potential motor damage

- Resonance frequency complications

Emerging Technologies in 2024

Smart Reactive Compensation Systems

- AI-driven dynamic compensation

- Real-time power factor monitoring

- Predictive maintenance integration

Implementation Checklist

- Obtain manufacturer motor data

- Measure no-load current

- Calculate required KVAR correction

- Select appropriately sized capacitor

- Implement monitoring systema

About Nengfu Electrical

A pioneer in electrical system solutions, Nengfu Electrical drives digital transformation in the energy sector. With ISO 9001, 14001, and 45001 certifications, we're committed to innovation and excellence.

Transform Your Electrical System Today! Contact Our Experts for a Free Efficiency Audit